High

Accuracy Angular Measuring High

Accuracy Angular Measuring

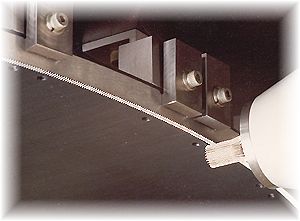

Rack

A unique feature of helicoidal rack is

that it provides correct gear action even when mounted on a curved

rather than straight surface. Angular measuring rack

occupies a minimum of axial space allowing rotary tables to be designed

for greatest stability. Robust hardware and accurate measurement

feedback and control is assured by the use of SEL Precision Series Rack

and Pinion Systems.

Our Angular Measuring Rack (AMR) system

is supplied as a rack set to suit a specified diameter. The range

is from 570 mm upwards with close intervals between possible working

diameters. When included in an initial design concept, the AMR

gives particular benefits. The measuring radius is a large

percentage, usually from 50 to 80 percent, of the maximum working

radius, producing high repeatability.

A very practical benefit to the design

of, for instance, a rotary or indexing table is that no axial space is

needed below the table. This makes it lower and stiffer, along

with other parts of the machine, increasing machine working rates and,

again, repeatability. |